-

4 Ways Injection Molding Flaws Can Impact Your Business

In the plastics molding business, it’s unrealistic to think you will get perfect parts off the line 100 percent of the time. However, frequently having flawed parts that need to be remade shouldn’t be a standard part of your business, either. Here are 4 ways injection molding flaws can negatively impact your business: Costs You…

-

3 Ways Chem-Pak Can Help Your Office Furniture Manufacturing Business

Your office furniture manufacturing business relies on a careful balance of function and aesthetics. All your equipment must be visually appealing and in top functioning condition. Your employees must be well-trained and you must use high-quality raw materials in combination with excellent manufacturing processes. If any of these factors are out of balance, you can…

-

4 Ways Chem-Pak Can Help Your Automotive Manufacturing Business

Running an automotive manufacturing business brings with it lots of variables. To produce quality automotive parts, you need to trust that a variety of factors are all in place, including that your raw materials are of good quality, your machines are running properly with all control parameters in place, your molds are well designed and…

-

5 Ways Chem-Pak Can Improve Your Business’s Bottom Line

Running your manufacturing business is expensive. You have to pay for equipment upkeep, your floor space, employee salaries, raw materials … The list feels never-ending. While some amount of loss is expected on your production floor, constantly discarding and remanufacturing parts doesn’t have to be one of those expenses. Rather than constantly adjusting your machinery…

-

Injection Mold Flaws & How to Prevent Them: Discoloration, Gloss, Jet, & Drag

Frequent care and maintenance of all your injection molding equipment, as well as proper employee training, can go a long way to preventing expensive injection molding flaws. While you can’t completely eliminate flaws from your injection molding business (Wouldn’t that be nice?), you can spend some time tackling problems head-on and trying to find solutions…

-

Injection Mold Flaws & How to Prevent Them

Contamination, Splay, & Delamination As we said in our last blog post, injection molding practitioners can’t completely avoid all flaws and defects during the process. However, taking extra precautions to correct any flaws that may occur goes a long way to maintaining the profitability of your business and your integrity in the eyes of your…

-

Injection Mold Flaws & How to Prevent Them: Flow Lines, Knit Lines, & Blush

Preventing Flow Lines, Knit Lines, & Blush Injection molding isn’t an exact science, and there is a lot that can go wrong in getting your plastic pieces ready for market. While frustrating and sometimes costly, injection molding flaws can’t be fully avoided. However, you can make small changes to your injection equipment and processes to…

-

Coming Soon!

Blog Coming Soon! Chem-Pak is excited to start sharing our knowledge and expertise on the Specialty Coatings, Contract Aerosol and Liquid Packaging industry. Check Back Soon for More!

-

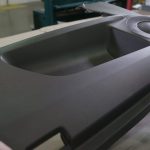

Types of Flaws Repaired

Plastic Flaw Repairs Per-Fix Flaws Repaired